Our services are continuously adapted to market trends and to your demands. In the automotive sector, we develop, simulate, code and test for e-mobility, electrified drive trains and conventional transmissions. Our numerous references and experiences include the development of electrical and hybrid powertrains, e-axles, transmissions and control units, as well as high-voltage applications, for power electronics or on-board-chargers. Get in touch with us and convince yourself of our performance, capabilities and complete engineering service from a single source.

In mechanical and industrial engineering, you benefit from our competencies and expertise in a wide range of areas. From research to series development, product and process optimization of mechatronic components, electrical and electronic modules or complex manufacturing and production machines. Our engineers realize the planning, management, conception as well as development and programming of ideas and projects. From the creation of specifications to the validation of your products and systems, you benefit of a complete service from a single source.

We create software and software modules for you in compliance with V-model in complete software development cycles. From definition of requirements through software architecture up to functional tests in SiL and HiL environments, our software designer can support you with software modules or with system development. They work and code according to the established processes, standards and regulations such as A-SPICE, ISO 26262 (up to ASIL D), AUTOSAR, etc. If required, our experts can be integrated into your processes in accordance with the tasks. Take advantage of our experience and our wide range of technologies and software development tools that have been successfully proven in projects for automobile manufacturers and industry as well as

From 48V to the high voltage with up to 800V, we develop power electronics such as inverters, converters and chargers. Starting with requirement management, selection of electric and electronic components and definition of the hardware architecture, our developers create circuits, layout and routing of the circuit boards and round off this service with mechanical integration and fluid dynamic simulations. KONDI experts develop process-compliant solutions that meet all your requirements and specifications. Our digital tools enable us to provide you with various simulations, like EMC, signal and supply integrity or low-loss current routing. We also take over the complete creation of documentation including all data according to your or your suppliers’ specifications for the production of the printed circuit boards (PCBs).

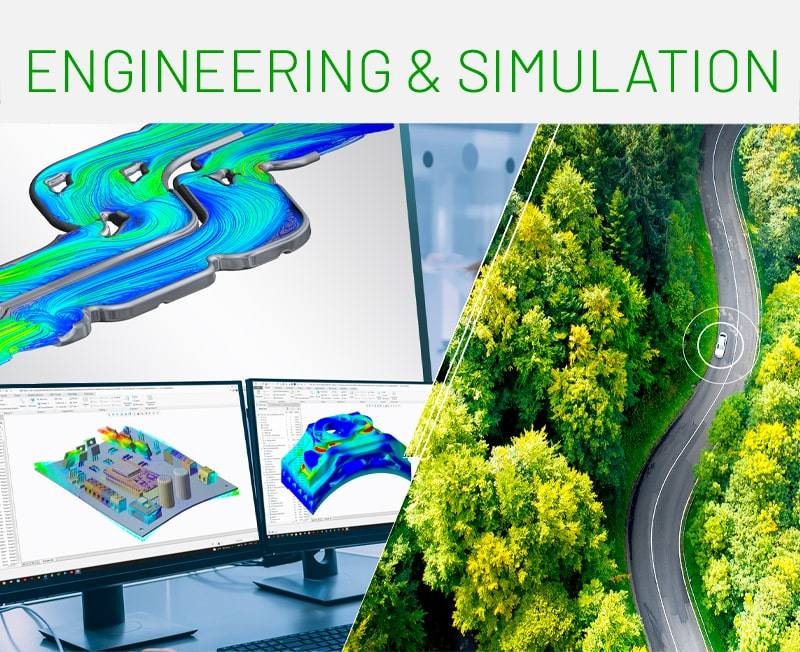

With many years of experience as well through modern methods and tools, we develop, simulate and optimize your products and create cost-effective, robust and manufacturable designs that meet your requirements. Our engineers support you along the entire product development process from requirement engineering through concept creation up to design and simulation e.g., mechanics (FEM), fluid mechanics (CFD), heat transfer, tolerance calculation. In this way, they secure function, production and assembly of your components and systems, create life-time predictions and optimize product properties. As your development partner, KONDI takes responsibility for system development or development and integration of sub-systems for instance e-motors, transmissions and power electronics.

Or simply leave your email address – we will get in contact shortly:

In our test center we test components, assemblies or systems for automotive and non-automotive applications for you. Our testing services include electrical, mechanical or climatic cycles and their combinations, for example according to the standards LV 124, ISO 16750-4, DIN EN 60068-2 or your own testing cycles. You can entrust the entire testing process to us. Our testing and validation engineers design and manufacture test adapters, record and evaluate measurement data, execute inspections of the specimen and create test reports. We can take full responsibility for functional testing, environmental testing and endurance testing. Or you can book our testing and validation facilities and infrastructure to use it with your own experts and your own specimens.

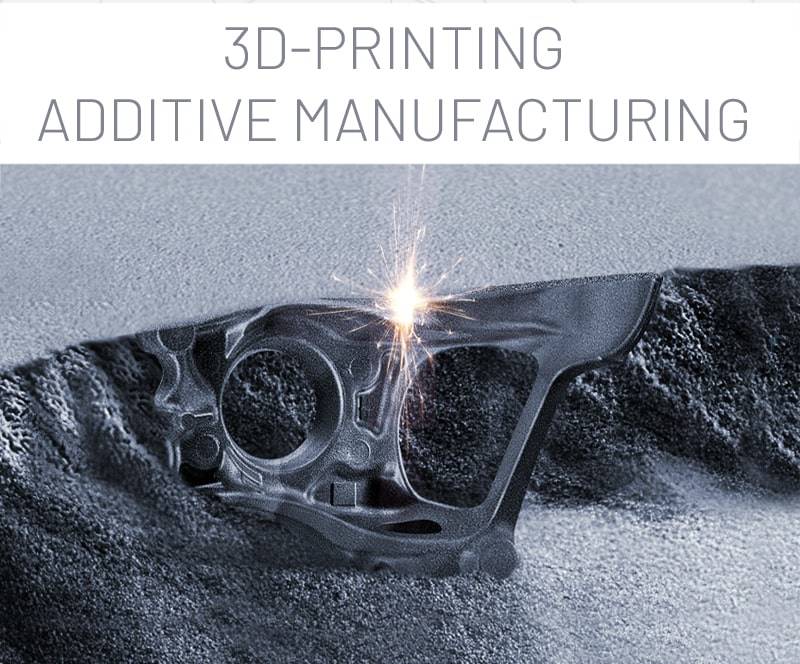

We offer 3D printing or additive manufacturing as a supplementary service in the framework of our projects or as a stand-alone service based on your data and models. Our specialists take care of the data preparation and data conversion for you and then generate the samples and components, either on our own printers or on external special devices. Whether early functional models in your innovation process, samples for packaging studies and installation tests, structure-optimized components or small series, with 3D printing or additive manufacturing, there are hardly any limits. Benefit from our expertise and from the new possibilities as time and weight saving offered by these modern processes.

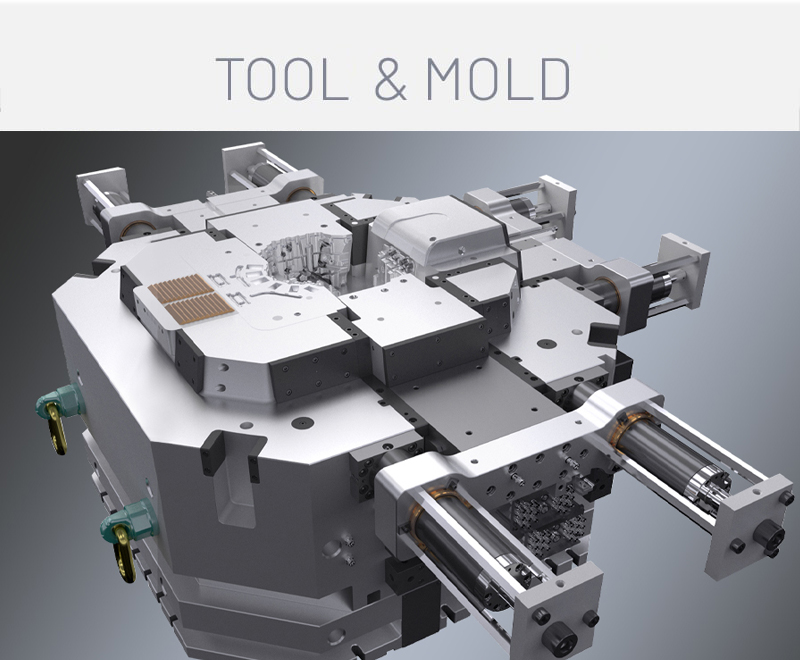

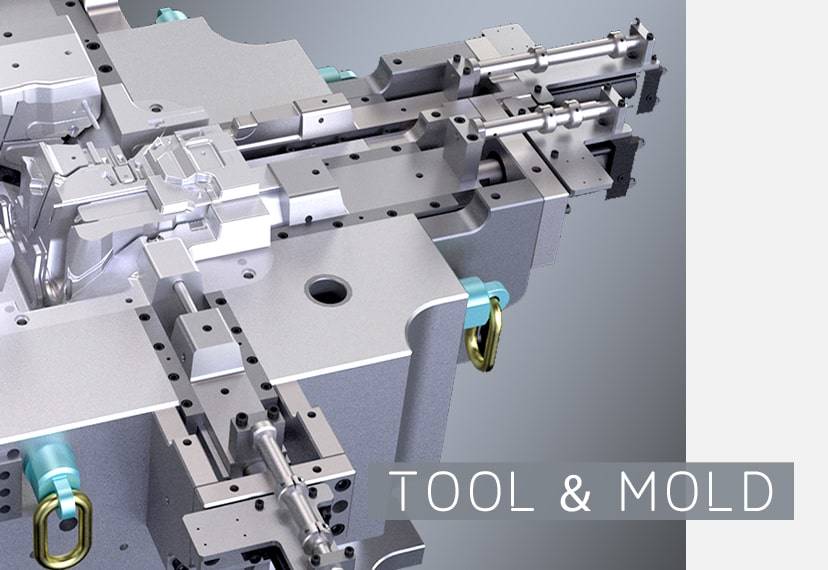

Our experts for primary shaping and casting processes will create tool concepts for you and design tools and molds, even for the most complex metal or plastic components. In order to achieve the desired component features or casting quality, they evaluate simulations of the filling, cooling and solidification processes. Depending on your production volumes, develop KONDI experts for you the right tool strategy with smart and efficient cooling concepts for prototype and serial tools, as well as intelligent interchangeable inserts Benefit from our know-how in a wide range of casting technologies as well from our long-term cooperation with many leading tool and mold makers and foundries.

Hier können Sie Ihre E-Mail-Adresse hinterlassen –

wir melden uns umgehend

KONDI GmbH / ENGINEERING | Im Zukunftspark 5 | 74076 Heilbronn

KONDI GmbH / ENGINEERING & TESTING | Inselwiesenstraße 8 | 74076 Heilbronn

Home Unternehmen Leistungen Karriere Referenzen Kontakt Kundenportal Impressum AGB Datenschutz

Are you interested in Tool & Mold?

Or just leave your email address – we will get in contact soon:

Are you interested in

Tool & Mold?

This will close in 0 seconds

Are you interested in 3D-Printing & Additive Manufacturing?

Or just leave your email address – we will get in contact soon:

Are you interested in

3D-Printing?

This will close in 0 seconds

Are you interested in Testing & Validation?

Or just leave your email address – we will get in contact soon:

Are you interested in

Testing & Validation?

This will close in 0 seconds

Are you interested in INDUSTRIAL ENGINEERING?

Or just leave your email address – we will get in contact soon:

Are you interested in

Industrial Engineering?

This will close in 0 seconds

Are you interested in Powertrain?

Or just leave your email address – we will get in contact soon:

Are you interested in

Powertrain?

This will close in 0 seconds

Are you interested in Hardware Development?

Or just leave your email address – we will get in contact soon:

Are you interested in

Hardware Development?

This will close in 0 seconds

Are you interested in Software Development?

Or just leave your email address – we will get in contact soon:

Are you interested in

Software Development?

This will close in 0 seconds

Are you interested in Engineering & simulation?

Or just leave your email address – we will get in contact soon:

Are you interested in

Engineering & Simulation?

This will close in 0 seconds